By Melissa Beall

MATERIALS DEFINE AN AGE. CIVILIZATIONS ARE MEASURED BY THE STONE AGE, BRONZE AGE AND IRON AGE. MOST RECENTLY, THE PLASTICS AND SILICON AGES. AFTER MUCH ANTICIPATION, 2022 SAW THE DAWNING OF THE GRAPHENE AGE, WITH A WIDE SWATHE OF USES FOR THIS WONDER MATERIAL IN

PRODUCTS.

On average, at least one graphene-enhanced product was introduced every week in 2022.

“Graphene is on the cusp of launching a fourth Industrial Revolution,” says Ray Gibbs, a graphene commercialization expert based in Manchester, England, where graphene was first isolated in 2004. “The graphene industry is working hard at producing high quality, consistent material that over time is capable of opening up a $100 billion market for high tech graphene-enhanced products.”

And yet, most people don’t know what graphene is. But soon, Gibbs adds, “graphene will touch the lives of almost everyone, almost every day.”

What is Graphene?

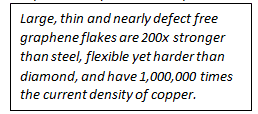

Graphene is the lightest, strongest, thinnest, best thermal and electricity-conducting material ever discovered. “Graphene is one of the most disruptive materials of all time,” says Brad Larschan, CEO of graphene flake manufacturing technology company Avadain, Inc.

Graphene comes from the humblest of origins – flake graphite, an abundant form of carbon which is best known as pencil lead. But when flake graphite is separated into 10 or fewer atomic layers, the incredibly strong carbon bonds in its unique 2D hexagonal structure, sp2 hybridization and very slim atomic thickness confer its fantastic combination of properties.

“The vast number of products, processes and industries for which graphene could create a significant impact all stems from its amazing properties,” according to the University of Manchester. “No other material has the breadth of superlatives that graphene boasts, making it ideal for countless applications.”

Graphene is an additive – it makes other materials better

“Graphene is starting to turn into what I like to call an ‘invisible additive’,” says Liam Critchley, a prominent writer and journalist based in England specializing in chemistry and nanotechnology. “Graphene is being used to enhance existing products like any additive material does, but such a small amount is required that you wouldn’t even know it’s there, unless marketed as such. So, someone could add a very small amount of graphene into one of their composite products, reap the benefits, and you’d be unlikely to know about it unless it was stated. And that’s the beauty of graphene for low tech and low value applications.”

Depending upon the quality of graphene, mixing in a tiny bit can significantly enhance the fundamental properties of products and materials. “Adding 0.01%-0.50% to other materials can drastically improve their properties,” says G6 Materials Corp.

Tennessee-based Avadain substituted just 0.5% of large, thin and nearly defect free graphene flakes for two leading conductive materials in super-capacitors enabled faster charging/discharging, 100% depth of discharge and increased power density. It also enabled constant specific capacitance as the discharge current increases, resulting in more efficient energy delivery and without loss. In stark contrast, the leading materials currently used had declining specific capacitance.

2022 saw a surge of products enhanced with lower quality graphene

In an October 2019 lecture at London’s Royal Society on “The First 15 Years of Graphene”, Nobel Laureate Konstantin Novoselov said the first commercial graphene-enhanced product was a tennis racket. Graphene slowly made its way into a few other consumer products, including motorcycle helmets, bicycle tires, fishing rods and a very expensive watch made by the Formula 1 supercar manufacturer McLaren.

Graphene and its derivatives come in a wide range of qualities. Methods of producing varying quality graphene materials include graphene oxide, reduced graphene oxide (rGO), graphene nano-powder, nanoplatelets, CVD graphene sheets and more. “The market now realizes that there are many graphene materials and not all are equal,” observes emerging technologies research firm IDTechEx.

“We’ve been through a great hype, and a great depression. Now, real graphene applications are entering the market, and the material is making a change across many industries,” observes Ron Mertens, founder and CEO of Graphene-Info.

“We saw a significant uptick in graphene’s commercial adoption in 2022 for three main reasons: producers are able to supply commercial quantities; end-users have renewed interest in the material; and, only a small amount is needed, making it a cost effective solution,” says Terrance Barkan, Executive Director of the leading trade industry association, The Graphene Council.

The Graphene Council reports that some 300 companies worldwide “claim to produce one or more forms of graphene”, and that global production “capacity is being added rapidly”.

So, what are some of the products with lower quality graphene that found their way into widespread use in 2022?

So, what are some of the products with lower quality graphene that found their way into widespread use in 2022?

Perhaps the biggest volume use is in road construction, where the material confers enough flexibility and strength to significantly “reduce the need for maintaining and renewing highways,” according to ontheroadtrends.com.

Cement and asphalt are among the highest greenhouse gas emitters. The manufacturing of cement is responsible for 8% of worldwide emissions and, according to the BBC, only stands behind China and the US as the biggest greenhouse gas emitters. “The use of graphene in small amounts to build highways could have the effect of reducing them by between 25%-33%,” adds ontheroadtrends.com. The University of Manchester notes that adding small amounts of graphene results in a 30% increase in concrete’s strength.

Sub-optimal quality graphene is also being used “in concrete to make it more robust, durable and flexible,” writes civil engineer Muhammad Adeel Ahsan. “The incorporation of graphene can increase the lifespan of buildings by reducing cracks and corrosion.”

Adam’s Polishes uses graphene oxide in car care products to deliver superior protection. “Our Graphene Ceramic Coatings are an evolution of our traditional quartz (SiO2) based ceramic coating offerings,” the company explains. “We are very proud to offer this technology – we have received a large amount of positive feedback and reviews on how our Graphene Ceramic Coating and other reduced graphene oxide infused products perform, their ease of application, and the wow-factor of the finished result on the vehicle.”

Lower quality graphene has been used to significantly increase the audio quality in MediaDevil Ingenia CB-01 earbuds. MediaDevil’s website claims that “Independent testing conducted by a leading British premium audio company found that, remarkably, [graphene] enhances both the high-end (treble) and the lower-end (bass) of the audio frequency wave.”

Lower quality graphene is also finding its way into headphones to produce higher quality sound. LG claims that its T-90 headphones use a graphene structure to reduce vibrations, producing a “crisp, natural soundscape with consistent tonal balance at any volume.” Ora Graphene claims to have taken graphene-enhanced headphones to the next level. Physics World enthusiastically wrote about the quality of Ora’s headphones. ORA headphones have also been endorsed by Los Angeles Philharmonic conductor Gustavo Dudamel, who says they provide “a level of clarity I’ve only ever experienced from the podium in front of an orchestra”.

Four companies say they used lower quality graphene to create what they claim are super-efficient power banks. According to digitaltrends, graphene keeps the device cool during recharging and “results in much more efficient performance, allowing the Apollo Traveller to achieve charging efficiency of 96 percent and last for 1,500 fast charging cycles, when most power banks only manage around 80 percent efficiency and promise 500 cycles.” ChargeASAP.com goes even further, writing that “Graphene power banks are a game-changer when it comes to fast, safe, and reliable charging. Unlike pure lithium polymer batteries commonly used today, graphene introduces higher energy density and conductivity – resulting in a lighter and more longer-lasting battery pack.”

British company Inov-8 is selling GRAPHENE-GRIP™ rubber on the outsoles of its running, hiking and fitness shoes to make athletic footwear lighter and more durable.

Industry is beginning to understand that the quality of graphene is key

While products enhanced with lower quality graphene are being launched in record numbers, industry’s biggest and, so far, unmet need is for high quality graphene as an additive to improve a wide range of high value products. Large (>30+ microns in lateral flake size), thin (<5 atomic layers) and nearly defect free flakes possess all of graphene’s superlative qualities. Simple graphite can be transformed into one of the most disruptive and valuable materials of all time. High-quality graphene flakes meet 80% of industry’s need for graphene as an additive material, while graphene with oxygen defects or small lateral flake size are considered lower quality because they possess only limited properties. Interestingly, graphene with oxygen defects or small lateral flake size are actually brittle. Researchers from Georgia Institute of Technology and Rice Universities reported that “perfect graphene can take about 100 Gigapascals (14 million pounds per square inch) of force before it breaks. But the imperfect graphene the researchers made can withstand only a tiny fraction of that, about 4 Megapascals (580 pounds per square inch).”

While products enhanced with lower quality graphene are being launched in record numbers, industry’s biggest and, so far, unmet need is for high quality graphene as an additive to improve a wide range of high value products. Large (>30+ microns in lateral flake size), thin (<5 atomic layers) and nearly defect free flakes possess all of graphene’s superlative qualities. Simple graphite can be transformed into one of the most disruptive and valuable materials of all time. High-quality graphene flakes meet 80% of industry’s need for graphene as an additive material, while graphene with oxygen defects or small lateral flake size are considered lower quality because they possess only limited properties. Interestingly, graphene with oxygen defects or small lateral flake size are actually brittle. Researchers from Georgia Institute of Technology and Rice Universities reported that “perfect graphene can take about 100 Gigapascals (14 million pounds per square inch) of force before it breaks. But the imperfect graphene the researchers made can withstand only a tiny fraction of that, about 4 Megapascals (580 pounds per square inch).”

High quality flakes are industry’s preferred form factor for graphene’s use as an additive, with an estimated $1 billion in pent-up market demand for large, thin and nearly defect free graphene flakes. So, what is holding back the Graphene Revolution?

“What industry is waiting for is a reliable source of large, thin and defect free graphene flakes to enhance high tech products,” notes Avadain’s Chief Commercial Officer, Phil Van Wormer. “This is when graphene is going to be world changing.”

Emerging technologies research firm IDTechEx recently reported that lower quality graphene supply is greater than current demand, but went on to observe that “it may not be in the type of graphene desired [by industry].”

“2023 will see even more low-tech graphene-enhanced products reach consumers and be utilized by industries, now that there is an abundance of lower quality graphene producers worldwide,” says Dr. Linh Le, CEO of New York-based Flextrapower. Flextrapower develops, manufactures and commercializes its reusable masks using lower quality graphene and is currently developing a N97+ equivalent mask using higher quality graphene. Le is part of the younger generation of graphene scientists who say they are excited by graphene’s potential to revolutionize industries.

“We will see the hockey stick growth curve in the next few years,” Le adds. “Companies are going to increasingly jump on the graphene bandwagon.”

What’s next for graphene?

Avadain sees billions of dollars of market opportunity for high quality graphene, with hundreds, maybe thousands, of applications for large, thin and nearly defect free graphene flakes as an additive, Larschan explained. He went on to say that high quality graphene can transform industries, including aviation, batteries, coatings, connected devices, defense, electric vehicles, electronics, filtration, medical devices, pharmaceuticals, renewable energy and space exploration.

“Imagine electric vehicle batteries that charge much more quickly by using a tiny amount of graphene on the anode. Imagine solar cells that have much higher light-to-electricity efficiency using graphene. And, imagine wind turbine blades that are lighter and stronger, so they won’t break. Also imagine a new generation of drones and electric airplanes that are lighter and more energy efficient. All of this is possible because of high quality graphene.”

“Imagine electric vehicle batteries that charge much more quickly by using a tiny amount of graphene on the anode. Imagine solar cells that have much higher light-to-electricity efficiency using graphene. And, imagine wind turbine blades that are lighter and stronger, so they won’t break. Also imagine a new generation of drones and electric airplanes that are lighter and more energy efficient. All of this is possible because of high quality graphene.”

The Graphene Council identified 45 industry sectors that can be transformed by graphene. It projects demand for all types of graphene will reach 300,000-600,000 metric tonnes annually, of which 10%-15% will be for high quality graphene.