By: Akanksha Urade

(Ph.D. Scholar at IIT Roorkee and Graphene & 2D Materials Science Writer)

The commercialization of graphene has been in the limelight in the nanotechnology community ever since it was isolated in 2004. With multiple commercially viable products already introduced, it is clear the global graphene market reached its inflection point in 2021. With demand for high-quality graphene rising extremely quickly, this megatrend is on the verge of burgeoning.

Obstacles to Commercialization of Graphene

One of the greatest obstacles to the commercialization of graphene in high value products is the absence of cost-effective, defects-free, and high-quality graphene at an industrial scale.

According to a recently published quality evaluation survey, most commercially manufactured “graphene” on the market is not a single or few-layer graphene sheet (1-10 atomic layer), as promised. Instead, these nanomaterials are a mix of graphitic (more than 1000 atomic layers) and other nano-carbonaceous particles or impurities having properties that are completely opposed to graphene. So, 95% of the market isn’t even graphene; it’s just a marketing word. In the long run, this will harm the graphene marketplace, affecting the rest of the distribution chain.

Another major hurdle will be to reach volume production in the next 3-5 years and taking down the cost to boost its commercial appeal. The Graphene Council estimates that, over the next few years, there will likely be a 300,000-600,000 MT in demand for graphene. Of this, an estimate 10%-15% of demand will be for high quality graphene for high value uses.

Graphene Flakes-An Emerging Megatrend for the 21st Century

Flakes are the preferred form factor for more than 80% of high value applications, including electric vehicle batteries, renewable energy, sensors, space exploration, medicine, and various other applications. However, there is no commercially available supply of large, thin (1-10 atomic layers) and defect-free graphene flakes at an affordable price. Industrial-scale production of high-quality graphene flakes is a niche market in which hardly any advanced materials manufacturers are concentrating.

Furthermore, it is critical to recognize that if the graphene flakes are smaller than 30 µm2, they become brittle and lack mechanical strength the smaller they get, making them unsuitable as an additive or substitute for structurally robust composite materials. Hence, the demand for graphene flakes is projected to skyrocket as soon as industrial quantities of affordably priced very high-quality graphene become available.

Avadain’s Breakthrough Technology

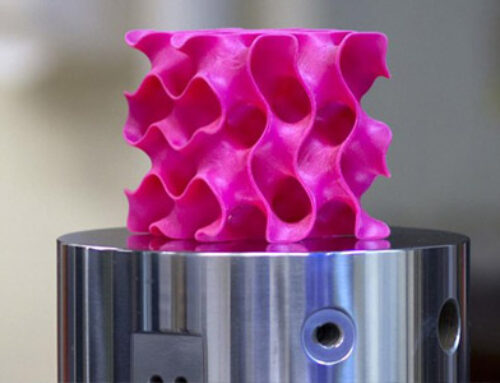

Avadain has successfully demonstrated a breakthrough, scalable, and environmentally friendly manufacturing process to produce large (average app 55-100 µm2), thin (avg 1 nm), and nearly defect-free graphene flakes (2-5 atomic layers) at affordable cost. Avadain technology uses optimized electrochemical exfoliation and expansion to separate the layers of graphite to produce single to few layers of graphene flakes with very few defects and a greater than 70% yield.

The key innovation is that during electrochemical exfoliation, the high negative potential (app. -60 V) is applied, resulting in intercalation and decomposition of the polar solvents in the electrolytes between the graphite layers. This causes enormous pressure that overcomes the Van der Waals attraction between the graphite layers and drives the sheets to exfoliate as flakes.

More importantly, during the exfoliation, the graphene flakes are partially hydrogenated to help exfoliate graphite into low defect graphene flakes. This is in contrast to the popular Hummers process, which uses very strong and environmentally unfavorable oxidizing chemicals to exfoliate graphite into graphene oxide flakes with too many difficult to remove defects from overoxidations.

Upscaling the Technology for Mass Production

Southwest Research Institute in San Antonio, Texas, is scaling up Avadain’s technique from batch to continuous flow. The company obtained an early investment from Panasonic. It recently received $3.77 million in project funding from the US Department of Commerce to scale up its environmentally friendly graphene flake manufacturing technique to mass production as part of a two-year project.

The first commercial production of graphene flakes will hit the market in the middle of 2024, with an annual capacity for each production line of two metric tons, i.e., 7-10 kilograms per day.

Toward a Brighter Future

Avadain aims to catalyze the Graphene Revolution by licensing its technology to advanced materials and enterprises with a mission critical need for high-quality graphene.